Fuel cleaning station for tank systems

In warm regions of the world, microbial infestation of fuel storage frequently causes major damage to combustion engines in machines, generators and aircraft. The problem of diesel pollution is to blame.

The interaction of microbiology, high outside temperatures and condensation in the fuel leads to the rapid growth of microbes in the bottom area of the fuel tank, which can quickly render all of the fuel in the tank unusable.

But there is a remedy for this:

The KRP 5000 fuel cleaning station from Krampitz

The diesel plague has no chance here. The KRP 5000 is one highly effective cleaning system, which disinfects the fuel using physical means and thus makes the diesel fuel permanently stable and storable.

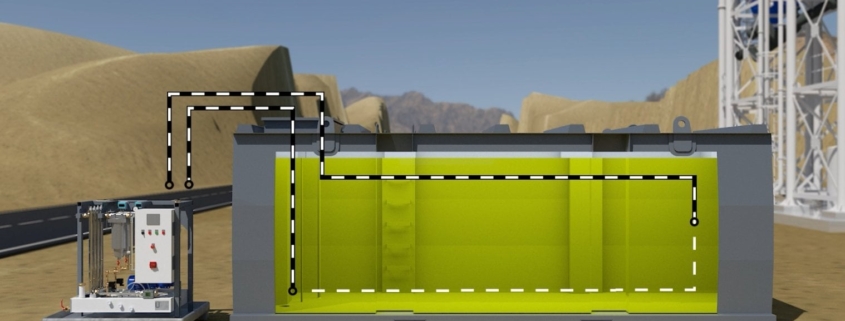

And this is how the fuel cleaning station works:

- The KRP 5000 is operated in a circuit as a bypass on a fuel storage tank. The fuel is sucked from the storage tank into the cleaning station, cleaned and then pumped back into the tank. This ensures a good flow of fuel throughout the entire tank and prevents dead zones from forming in the storage tank.

- Cleaning of fuel in the KRP occurs in two stages of treatment: filtering and disinfection.

- First, the fuel to be cleaned flows through the pre-filter, which works as a bag filter. Here the medium flows through a filter bag inserted in the support basket. Dirt and solids are retained in this way.

- The pre-cleaned filtrate is now transported by the pump into a water separator. The water separator contains a filter cartridge with hydrophobic properties. This does not allow water to pass through and separates all particles larger than 2 micrometers.

- The separated water collects on the bottom of the water separator where it is recorded by a sensor.

- The sensor sends a signal to the solenoid valve.

- The solenoid valve opens and the water flows towards the dirty water tank.

- The cleaned and water-free fuel now goes through the second treatment stage: disinfection.

- To do this, the fuel flows through special treatment tubes that are equipped with UV lamps.

- The UV light triggers a photochemical reaction that interrupts the genetic information for cell reproduction and metabolism. In this way, the microorganisms are deactivated and rendered harmless.

- At the end, the clean, disinfected and filtered fuel returns to the tank via the system outlet.

The KRP system has been installed in many projects at home and abroad for over 10 years. Due to customer requests, fuel samples were taken every six months at several locations analyzed by approved fuel laboratories. That was if the prescribed service intervals were adhered to The result is consistently excellent. The cleaned fuel meets the highest quality standards in terms of sterility and water separation.

Thanks to the fuel purification system from Krampitz, fuel can be stored permanently and diesel pollution has no chance.

Progress through technology. Krampitz tank system – cubically good.