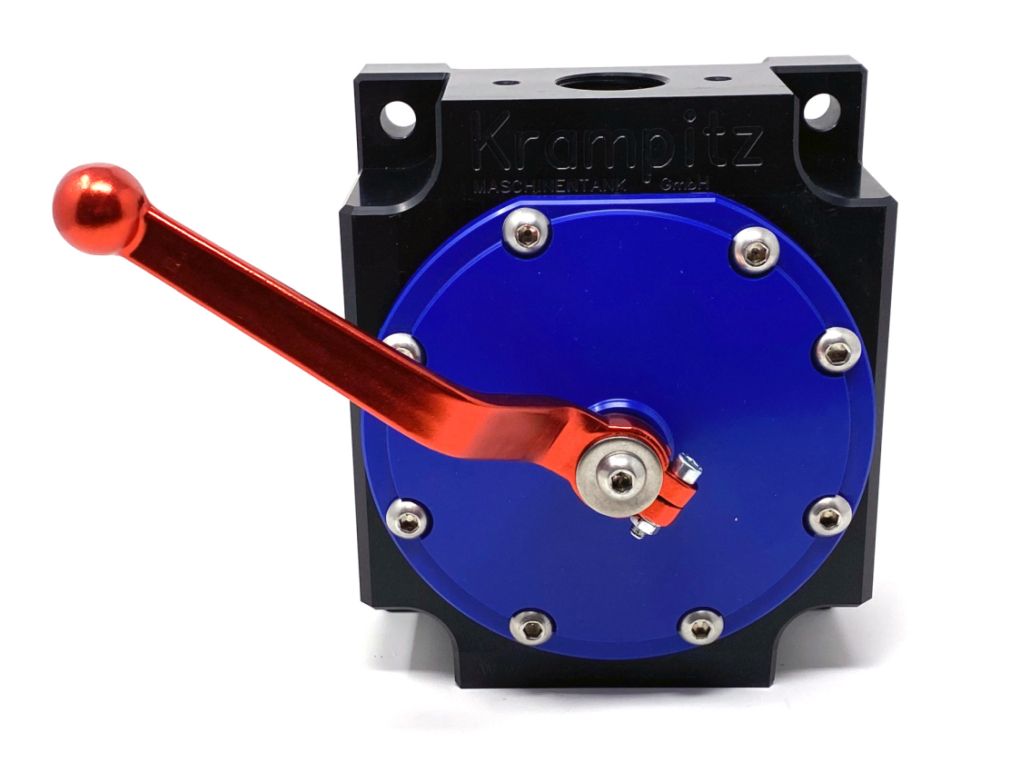

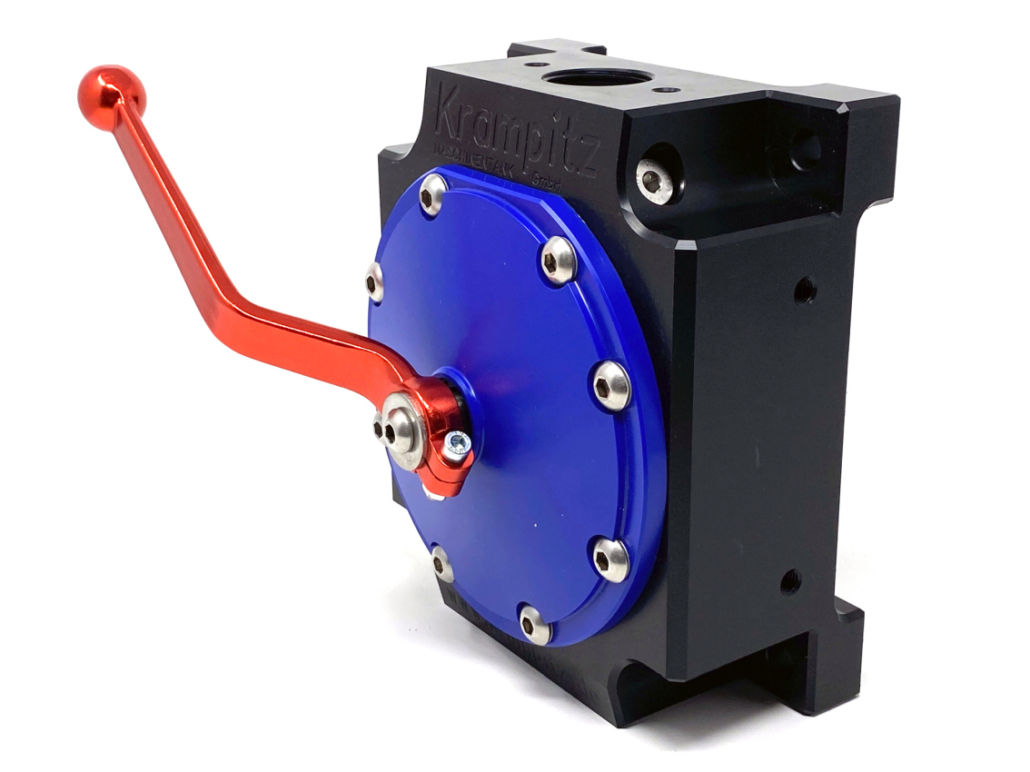

Double-acting hand wing pump

for urea, chemicals, water mixtures

This modern hand wing pump PH 2020 is a further development of the hand wing pump system that has been tried and tested for over 100 years.

We have redefined this pump with a new shape, modern high-quality materials, new functional details and perfect mechanical CNC machining. These new pumps work excellently and safely. Up to 2 bar excess pressure can be generated manually.

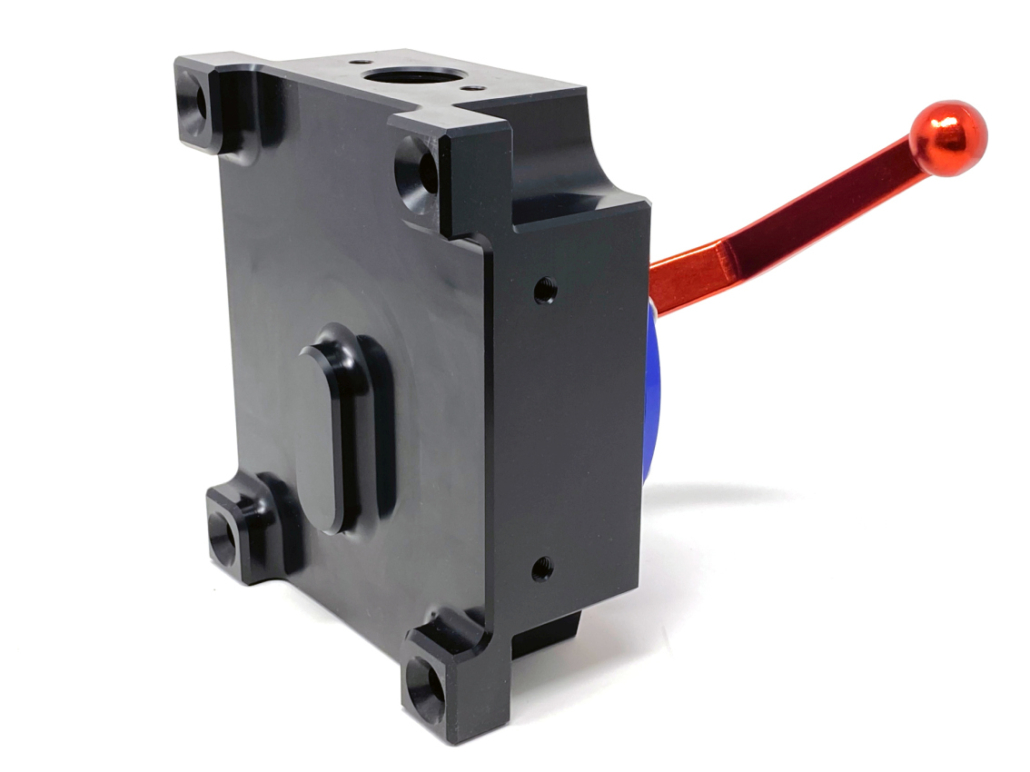

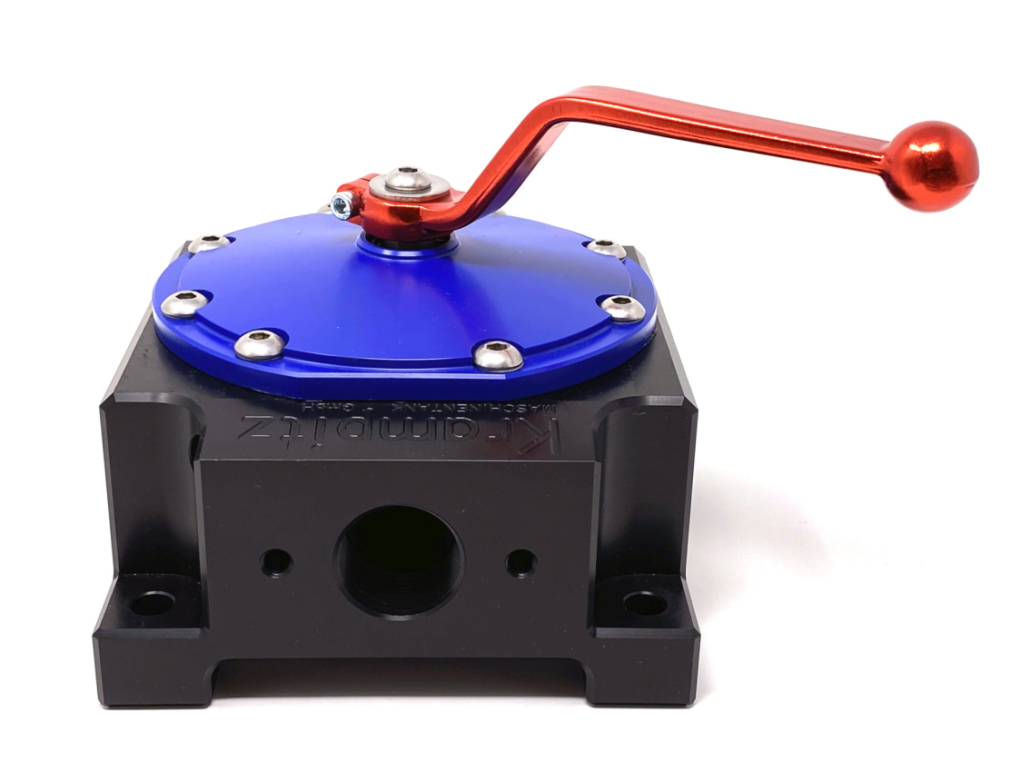

Four mounting holes in the rear wall of the housing enable secure attachment to machines or systems. A pouring opening in the top of the housing is used for easy pouring of the pump during initial commissioning.

Depending on the application, the pump housing is made of aluminum, gray cast iron or plastic. The pump shaft on which the pump blade sits is made of stainless steel. The pump blades inside the pump are made of brass, plastic or aluminum, depending on the application.

Data sheet:

Technische Angaben:

- Delivery rate: approx. 15 l/min

- Double strokes: 60/min (average value)

- Per double stroke: approx. 0,28 l

- Head: 15 m

- Suction height: 4 m

- Connection: G 1″ (IG)

- Weight: 4,15 kg

Main areas of application:

- Supply of diesel generators

- Petrochemistry, ship technology

- Construction industry and agriculture

- workshop

Construction materials:

- Housing: POM black/blue

- Internal parts: Al Mg Si1

- Shaft: stainless steel 1.4301

- Shaft seal: HNBR simmering DIN 3760